Nanoident Technologies is a privately held company founded in 2004 out o

f Austria with the aim of printing semiconductors, biometric assays, and photonic lab-on-a-chip systems with a method similar to that utilized by nanosolar. Nanoident has two major subsidiaries. The Austrian-based Nanoident Biometrics prints biometric sensors for security purposes, while Bioident Technologies, based in Menlo Park, CA, prints opto-electronic capabilities on lab-on-a-chip systems for diagnostics. Details on the financial investments made into Nanoident are unknown, but CEO Klaus Schröter claims to have received no venture capital money to fund R&D.

f Austria with the aim of printing semiconductors, biometric assays, and photonic lab-on-a-chip systems with a method similar to that utilized by nanosolar. Nanoident has two major subsidiaries. The Austrian-based Nanoident Biometrics prints biometric sensors for security purposes, while Bioident Technologies, based in Menlo Park, CA, prints opto-electronic capabilities on lab-on-a-chip systems for diagnostics. Details on the financial investments made into Nanoident are unknown, but CEO Klaus Schröter claims to have received no venture capital money to fund R&D.www.Nanoident.com

Subsidiaries

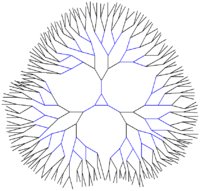

Bioident Technologies- Bioident prints opto-electronic capabilities on semiconductor based photonic lab-on-a-chip systems for detection of biological agents in food, water, and blood or tissue samples for diagnotic purposes. Bioident's technology integrates microfluidic lab-on-a-chip systems with printed light emitting and detecting electronic interfaces to create a novel platform in which samples can be easily illuminated and detected in real time for detailed analysis.

Nanoident Biometrics- Nanoident biometrics prints biometric sensors for use in identification softwares. Nanoident's biometric sensor are printed for touch screening, and test for fingerprints as well as blood and skin parameters on the surface of the finger. Nanoident seeks to use this technology in next generation wireless and internet communication, payment systems, as well as other identification solutions.

Products

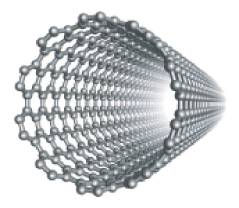

Semiconductor 2.0- This is Nanoident's platform for printed semiconductor-based products. This printing process allows for custom designed devices to be produced at a fraction of the cost as traditional semiconductor fabrication plants.

PhotonicLab- This platform enables real-time, in-situ and multi-parameter detection and analysis capabilities for lab-on-a-chip systems. The technology improves on the capabilities of traditional lab-on-a-chip technology while maintaining the cost-effectiveness inherent in the technology.

News

3.08.2007- Bioident receives the 2007 Frost & Sullivan enabling technology of the year award

3.08.2007- Biodent announces first complete lab-on-a-chip system based on printed semiconductor technology

3.13.2007- Nanoident opens first manufacturing plant for printed opto-electronic semiconductor sensors

9.18.2006- Bioident technologies opens U.S. headquarters in Menlo Park, CA

6.26.2006- Nanoident announces its biometrics division

11.28.2005- Nanoident builds the world's first factory for organic semiconductor sensors

10.10.2005- Nanoident wins the coveted Austrian Innovation award

6.30.2005- Nanoident presents first high resolution photodetector based on organic semiconductors

(FIGURE from Nanoident.com)